WHY?

Environmental problems such as marine and air pollution are usually caused by industrial wastewater, smoke and soot. A lesser known, innocuous cause of contamination, however, is the water discharged by ships.

Large ships take in fresh or seawater into tanks and cargo holds to help stabilize and balance a ship. Known as ‘ballast water’, this is what a ship draws in at its port of call, either before loading cargo or after unloading cargo. As the ballast water travels with the ship, it can be taken from one region to another that is thousands of kilometers away.

This is a problem because seawater contains sediments, plankton and a variety of small organisms. When ships discharge its ballast water at the port of call, the transfer of harmful aquatic organisms may occur, causing a huge impact to the balance of marine life.

In response to this growing concern, the International Maritime Organization (IMO) has adopted the “BWM Convention”, which will require all international ocean-going ships to install ballast water treatment systems onboard. This translates to more than 30,000 existing ships that will be fitted with ballast water treatment systems in the next few years.

How?

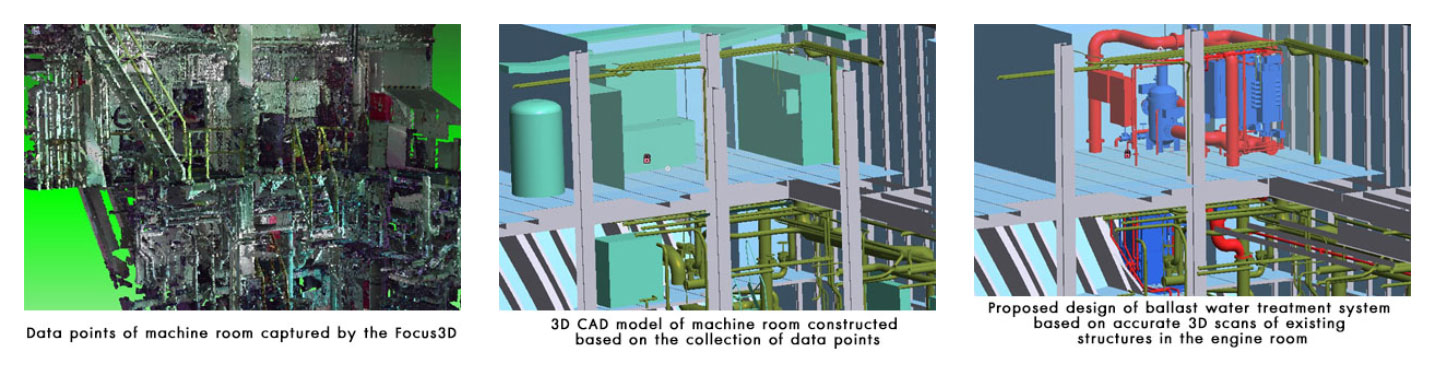

Motivated by the shipping industry’s need, a joint study group named “The Effective Use of 3D Laser Scanner” was founded, and the study explored the use of a 3D laser scanner to design the ballast water treatment system. The eight-member group of the study included ClassNK, Nippon Yusen Kabushiki Kaisha (NYK Line), Mitsui O.S.K. Lines (MOL), Kawasaki Kisen Kaisha, Ltd. (“K” Line), Monohakobi Technology Institute (MTI), Sasebo Heavy Industries Co., Ltd., Sanwa Dock Co., Ltd., The University of Tokyo and S.E.A. Systems, Inc.,

WHAT ?

3D laser scanning if the common tools utilized in all BWTS application nowadays. Due to its various benefits and extended applications, customer can progress not just in BWTS but also in Ship Maintenance & repair, as well as all other aspects of applications more effectively.

Application

- Time-Saving : BWTS Design can be done most accurately and fastest using 3D laser scanner

- System digital documentation: Asset management and 3D document for maintenance, planning, and extension

- Installing and repairing: collect detailed structural piping data for installing, repairing, or maintenance of Ballast Water Treatment Systems for optimized position.

- CAD Design and drawing with 3D Model: Using for extending structural design or create 3D modeling of existing structural systems that instead of Manual drawing

- Precious Measurement: Precision and easily pipeline measurement in an area where densely installed machines without the need to go directly on site.

Benefit

- Saving time and reduce worker, including the cost of working

- Reduce error accurately collecting from existing design on site.

- Evaluate and inspect include check cash for installing new structure with 3D Model.

- Evaluate and inspect include crack detection for new installing compare with 3D Model. Consider possibility of system installation in the area.

- Easily and conveniently planning for work procedures and engineering.

ภาษาไทย

ภาษาไทย